CHANGE THE WAY YOU CLEAN!

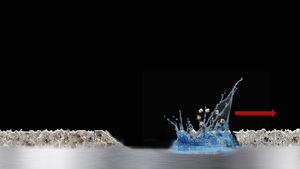

Ice Blasting is an innovative wet and dry ice blasting technology. Our machines are less expensive to operate, use 95% less water than traditional blasting methods, are safer, and are environmentally friendly.

Twice the Machine. Why have more tools when you have one that does it all? Wet ice for when you need to get the job done, and dry ice when you need to keep it dry.

ANY ICE, ANY TIME, ANYWHERE. SAME MACHINE!

A&M Marine is your Ice Blast distributor. We offer complete Ice Blast systems, including ice storage units, compressors, and self-contained trailers. We can help you design the perfect Ice Blasting system for your needs. We will work with you to understand your specific applications and recommend a complete solution.

Need an air compressor? A&M is an authorized Cummins dealer. We provide full factory-authorized service on everything we sell.

Contact us today for more information on Ice Blast systems.

Ice blasting is the environmentally friendly and low-cost alternative

to traditional sand & glass blasting systems.

With A&M Enviromental, you can choose standard Ice or Dry Ice!

Ice or Dry Ice. You Choose!

WHY CHOOSE ICE?

- Using Ice will significantly reduce your operating costs.

- Ice will not sublimate like dry ice. Under proper storage, it will virtually last forever.

- Ice reduces airborne contaminant levels compared to other blasting technologies.

- Ice is a non-hazardous material, unlike dry ice and all other blasting media.

What is Wet-Ice Blast?

High-pressure water blasting, also known as hydro blasting or pressure washing, uses up to 35 times more water and thousands of gallons per hour. High-pressure water wash systems generally require the use of chemicals to enhance the cleaning process. Ice Blasting uses no chemicals, thus, worker health risks are eliminated, and there is no contaminated water to be disposed of.

Resource Usage

Our patented Wet Ice Blast technology has a low media input cost because it only requires conventional ice in comparison to systems that use dry ice or sand, which has a significantly higher operating cost.

Environmental Impact

Blasting using dry ice, sand, plastic beads, or other media poses higher environmental impacts as additional materials must be disposed of in landfills. Our Ice Blasting system is a sustainable and environmentally responsible alternative to other blasting technologies.

Employee Safety

In the industrial cleaning sector, airborne contaminants are a prime concern when performing any cleaning task. Protective clothing and respiratory aid are necessary when using abrasive cleaning technology. Ice blasting is the only true dustless blasting method available on the market today.

Lead-based paint abatement, which includes one of the most harmful substances to remove (lead) and consequently the most regulated, has the requirement for masks at an airborne exposure of 0.05 milligrams of lead per cubic meter of air. In product testing, the maximum outdoor airborne lead contamination using Ice Blasting was less than 1/10th of the required maximum for unprotected work. Ice Blast is extremely effective in trapping airborne contaminants.

Cleaning Effectiveness

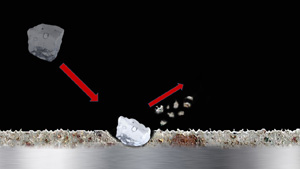

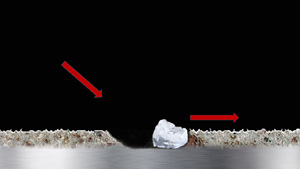

The cleaning method used in wet-ice blasting falls under three steps:

Bulk Removal: The stage where major contamination is first removed. Typically this is a physical removal by displacement (i.e., Momentum transfer). This step is, therefore, best achieved with a material that transfers its momentum efficiently to contamination. Solids, like ice, have better momentum transfer than liquids as they do not flow around strongly adherent contamination.

Detail Cleaning: The stage where some form of mechanical agitation, such as scrubbing or polishing, is provided to remove minute quantities of the remaining contamination from the surface. By definition, scrubbing means two solids moving relative to each other under applied pressure. As a blast-cleaning agent, water cannot offer this property.

Final Rinse: The removed contamination is rinsed away. Water is a universal solvent for this action. Many alternatives to ice blasting require an additional rinse on top of the blasting action.

Dry Ice? Yes! We do that too. Same machine!

What is Dry Ice Blasting? Dry Ice blasting machines are used in cleaning applications where moisture is an issue. In order to cover those areas, the Ice Blast industrial cleaning machine can also process dry ice.

PRODUCTS

A&M Environmental offers a variety of cutting-edge solutions in the ice-blasting industry. We have solutions that blast using real ice cubes and systems that blast with BOTH real ice and dry ice in the same machine.

ANY ICE. ANY TIME. ANYWHERE.

ICE OR DRY ICE AT THE TOUCH OF A BUTTON

Ice Blasting machines by A&M give you the option to switch between Ice and Dry Ice blasting mode with just the push of a button.

Pressing the CO2 button on the control panel retracts the jaws, allowing the dry ice to pass through without issue. There is no longer a need to haul multiple machines for different applications as one machine meets all demands.

TECHNICAL SPECIFICATIONS

- Superior internal ice crusher

- Non-pressurized 90lb hopper

- 200 lbs of dry ice pellets

- Variable feed rate: 0 – 5 lbs per minute

- Empty weight: 535 lbs

- Low levels of airborne contaminants

- Operating Pressure: 80 PSI – 190 PSI, 185 CFM – 425 CFM

- Flexible nozzle configurations

- Simple operating controls

- Zero chemicals required

- Anodized exterior panels

- Compact 42″x28″x47″ (LxWxH)

- Stainless steel option available

- 120V/12A

NOZZEL COLLECTION & ACCESSORIES

The Nozzle for the Ice Blasting system has been touted as some of the best in the industry. Designed by a NASA scientist who specialized in asteroid space particles hitting the International Space Station, these nozzles have been optimized for maximum ice velocity.

Have a specific application? We can work with you on a custom design. We also provide a variety of accessories, from coolers to ice makers. Get in touch today to discuss your needs.

5 Elements

There are so many different industrial blasting methods and applications. With an Ice Blasting system from A&M, you can keep things simple! Get a bag of ice cubes from the local marina or gas station, toss them into your machine, point the nozzle at the surface you want to clean, and pull the trigger. It doesn’t get much simpler than that!

There are millions of different applications for Ice Blasting. To show you the versatility, we’ve broken them down into the five basic elements.

These are the 5 Elements to Clean: Earth, Metal, Water, Wood, and Fire.

CLICK ON THE IMAGES BELOW FOR MORE INFORMATION ON EACH APPLICATION.

Contact us today and learn how Ice Blast by A&M can solve your cleaning needs!