Marine Diesel Engines Are Complex

Marine diesel engines are complex machines that are designed to provide reliable and efficient power for boats and ships. The complexity of marine diesel engines is due to several factors, including their high power output, durability requirements, and unique operating conditions.

One of the main challenges of marine diesel engines is their high power output. Marine engines must be capable of producing enough power to propel the vessel through the water, sometimes at high speeds, while also providing power for other onboard systems such as lighting, communication, and navigation. To achieve this level of power output, marine diesel engines are typically larger and more robust than their land-based counterparts, and they often have multiple cylinders to provide sufficient power.

Durability is another critical factor in the complexity of marine diesel engines. The engines must be able to operate for long periods, often in harsh environments such as saltwater, without suffering from corrosion or other forms of wear and tear. Marine engines are built with materials and designs that are specifically tailored to withstand the rigors of marine use, such as corrosion-resistant coatings and robust cooling systems.

Another challenge of marine diesel engines is their operating conditions. Marine engines must operate under a wide range of conditions, including varying temperatures, pressures, and loads. This requires sophisticated control systems that can adjust the engine’s performance to optimize fuel efficiency and power output while maintaining the engine’s durability.

Marine diesel engines are also subject to strict regulations and safety standards. They must meet emissions standards set by regulatory agencies and incorporate safety features such as automatic shutdown systems in case of an emergency.

Overall, the complexity of marine diesel engines requires specialized knowledge and expertise to design, install, and maintain. Regular maintenance and proper operation are essential to ensure the engine’s longevity and reliability, and failure to maintain the engine properly can result in costly repairs or even catastrophic engine failure.

Repair Costs Can Vary Widely

The cost to repair a marine diesel engine can vary widely depending on several factors, including the extent of the damage, the age and condition of the engine, and the availability of replacement parts.

Minor repairs, such as replacing a damaged impeller or a worn-out belt, may be relatively inexpensive and may cost a few hundred dollars. However, more extensive repairs, such as rebuilding the engine’s top end or replacing major components such as the cylinder head, can cost several thousand dollars.

The cost of parts is a significant factor in the overall cost of repairing a marine diesel engine. Marine engines often require specialized parts that can be expensive and difficult to obtain, especially for older engines. In some cases, parts may need to be custom fabricated, which can add to the overall cost of the repair.

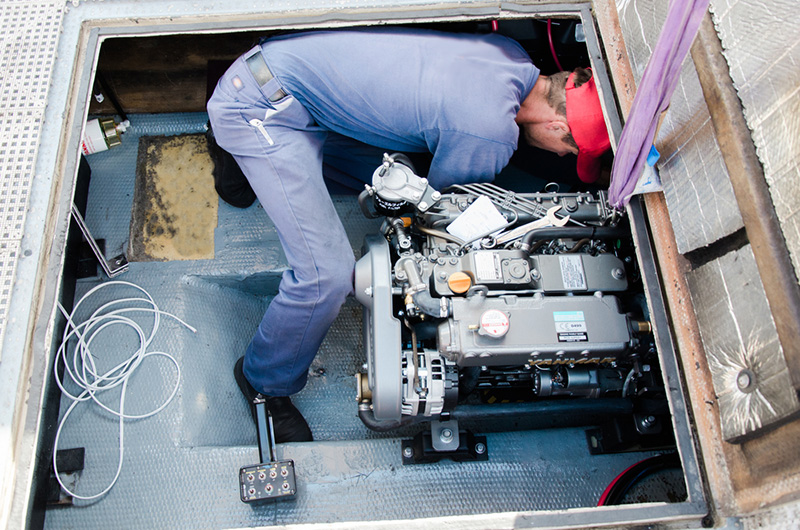

Labor costs are another significant factor in the cost of repairing a marine diesel engine. Because marine diesel engines are complex and require specialized knowledge and expertise to repair, labor costs can be high. Additionally, repairs to marine engines often require the removal and reinstallation of the engine, which can add to the overall cost of the repair.

Finally, the location of the repair can also affect the cost. Repairs performed in remote locations, such as on the water or in areas with limited access to repair facilities, can be more expensive due to the additional logistics and transportation costs involved.

Overall, the cost to repair a marine diesel engine can vary widely and can be quite expensive. Regular maintenance and proper operation can help reduce the risk of costly repairs and prolong the life of the engine, making it a worthwhile investment for boat owners.

Marine Parts Are Expensive

Marine diesel engine parts are often more expensive than parts for other types of engines, and there are several reasons for this.

One of the primary reasons for the high price of marine diesel engine parts is the smaller market for these parts. Compared to the automotive industry, the marine industry is much smaller, which means that the volume of production for marine diesel engine parts is much lower. This lower production volume results in higher manufacturing costs, which are passed on to the end consumer in the form of higher prices.

Another factor contributing to the high price of marine diesel engine parts is the specialized nature of these parts. Marine diesel engines operate in harsh environments that can cause rapid wear and tear on components, which means that these parts must be designed to withstand these conditions. This often requires the use of high-quality materials and specialized manufacturing processes, which can be more expensive than the processes used to manufacture parts for other types of engines.

Additionally, marine diesel engines are subject to strict regulations regarding emissions and safety, which can increase the cost of parts. Manufacturers must design and produce parts that meet these regulations, which can add to the overall cost of the parts.

Finally, the cost of distribution can also contribute to the high price of marine diesel engine parts. Marine engines are often used in remote locations or on boats that are difficult to access, which can add to the cost of shipping and handling the parts. Additionally, the specialized knowledge and expertise required to install these parts can also add to the cost of distribution.

Overall, the high price of marine diesel engine parts is a reflection of the specialized nature of these parts, the smaller market for marine engine parts, and the cost of meeting regulatory requirements. While these factors may make marine engine parts more expensive than parts for other types of engines, they are necessary to ensure the reliable and safe operation of marine diesel engines in the demanding marine environment.

Factory Trained and Authorized Mechanics

Using a factory-authorized mechanic to fix your marine diesel engine is generally recommended. Factory-authorized mechanics have been trained and certified by the manufacturer to work on their engines and have access to the latest technical information, diagnostic tools, and parts. They are also required to follow strict standards and procedures when repairing or servicing the engines, which helps to ensure that the work is done correctly and to the manufacturer’s specifications.

Using a factory-authorized mechanic can also help protect your warranty, as many manufacturers require that authorized service providers perform repairs and maintenance to maintain the warranty coverage. Additionally, factory-authorized mechanics often better understand the specific issues and quirks of the engines they work on, which can help them diagnose and repair problems more quickly and accurately.

That being said, there may be situations where a non-authorized mechanic can still properly repair your engine, particularly if they have significant experience and training in working on marine diesel engines. However, it is generally best to choose a factory-authorized mechanic for the most efficient and reliable repair work if possible.

Shortage Of Marine Diesel Mechanics

There is a shortage of marine diesel engine mechanics.

The skills required to work on marine diesel engines are specialized and require extensive training and experience. Many mechanics with the necessary skills and expertise to work on these engines are in high demand. They may be able to command higher salaries or prefer to work in other industries where the working conditions may be more favorable.

The marine industry can be unpredictable, and demand for repairs can fluctuate significantly depending on the season and the local boating culture. This means that many marine diesel engine mechanics may have difficulty finding steady work, which can make it challenging to build a career in this field.

Another factor contributing to the shortage of marine diesel engine mechanics is the aging of the existing workforce. Many experienced mechanics are approaching retirement age, and there may not be enough younger mechanics to replace them.

Finally, the high cost of training and education required to become a marine diesel engine mechanic can also be a barrier to entry for many people. The specialized tools and equipment required to work on these engines can also be expensive, which can make it difficult for small repair shops to invest in the necessary resources.

Overall, the shortage of marine diesel engine mechanics is a complex issue that is influenced by several factors. Addressing this shortage may require a coordinated effort from industry stakeholders, including government agencies, educational institutions, and marine engine manufacturers, to encourage more people to enter the field and support the training and education needed to develop the necessary skills and expertise.

Specialized Tool Are Required

Marine diesel engines are complex pieces of machinery that require specialized tools for proper maintenance. The tools required for marine diesel engine maintenance can be divided into several categories: diagnostic, cleaning, measuring, and specialized wrenches.

Diagnostic tools are used to identify and troubleshoot problems with the engine. These tools include engine analyzers, which are used to measure and analyze engine performance parameters such as fuel pressure, exhaust temperature, and oil pressure. They also include pressure gauges, vacuum gauges, and digital multimeters, which can be used to measure engine parameters such as cylinder compression, battery voltage, and alternator output.

Cleaning tools are used to maintain the cleanliness of the engine, which is essential for proper performance and longevity. These tools include wire brushes, abrasive pads, and solvents used to clean engine components such as fuel injectors, cylinder heads, and exhaust systems.

Measuring tools are used to ensure that engine components are within the manufacturer’s specifications. These tools include micrometers, dial indicators, and bore gauges, which are used to measure critical engine components such as piston rings, cylinder bores, and valve seats.

Specialized wrenches are used to access and remove engine components that are difficult to reach with standard tools. These tools include heavy-duty wrenches, oil filter wrenches, and torque wrenches, which are used to tighten engine components to the manufacturer’s recommended torque settings. Many manufacturers also require specialized software for computer diagnostics of electronic engine control systems.

In addition to these specialized tools, marine diesel engine maintenance also requires standard hand tools such as sockets, ratchets, pliers, and screwdrivers. It’s important to use high-quality tools that are specifically designed for marine applications, as they are built to withstand the harsh marine environment and can help prevent damage to the engine.

In conclusion, specialized tools are essential for maintaining marine diesel engines. These tools include diagnostic tools, cleaning tools, measuring tools, and specialized wrenches, and they are designed to help ensure that the engine runs smoothly and efficiently. Using the right tools for the job can help prevent damage to the engine and prolong its lifespan.

Environmental Regulations Add Cost

Marine diesel engine mechanics face various environmental regulations designed to protect the marine environment from pollution and reduce the emissions of harmful substances into the air.

One of the primary regulations that marine diesel engine mechanics must comply with is the International Convention for the Prevention of Pollution from Ships (MARPOL). This convention sets out guidelines for the discharge of pollutants into the air and water, including limits on the sulfur content of marine diesel fuel.

In addition to MARPOL, there are also regulations regarding the emissions of nitrogen oxides (NOx) and particulate matter (PM) from marine diesel engines. These regulations, which are implemented by organizations such as the International Maritime Organization (IMO) and the Environmental Protection Agency (EPA), require installing specialized equipment and using low-sulfur fuels to reduce emissions.

Marine diesel engine mechanics must also comply with regulations related to the disposal of hazardous materials, such as used engine oil and filters, as well as regulations related to the handling and storage of chemicals used in the maintenance and repair of marine engines.

To comply with these regulations, marine diesel engine mechanics must undergo specialized training and certification to ensure that they can properly handle and dispose of hazardous materials and install and maintain the specialized equipment required to reduce emissions.

Overall, the environmental regulations faced by marine diesel engine mechanics are necessary to protect the marine environment and reduce the emissions of harmful substances into the air. While compliance with these regulations can add to the cost and complexity of marine engine repair and maintenance, ensuring that the marine environment is protected for future generations is essential.

The Importance Of Maintenance

Maintaining your marine diesel engine can significantly increase the value of your boat.

It is important that you follow your engine operator’s manual maintenance schedule. Not only will this keep your engine in top running condition, but it will ensure that you maintain the warranty coverage. Regular maintenance does not just mean oil and filter changes. It includes servicing, heat exchangers, aftercoolers, risers, hoses, gear coolers, antifreeze flush, fuel injectors, valve adjustments, and anode replacement. Make sure you follow both time todo and hours intervals for recommended maintenance. If you don’t use your boat a lot, don’t just look at the hours. Maintenance items will often “time-out” long before the hours between maintenance is reached.

For example, for their popular D4 series, Volvo specifies the following maintenance “Every 200 hours OR once every year, whichever comes sooner.”

- Crankcase ventilation filter. Change

- Air filter. Change

- Exhaust pipe. Check.

- Drive belts. Check belt tension.

- Compressor. Check/change oil level.

- Seawater pump. Check/replace impeller

- Sacrificial anodes. Charge air cooler heat exchanger Check/replace

- Fuel filter/fuel pre-filter. Change

- Reverse gear. Change oil and filter

- Outboard drive. Change oil *3)

- Outboard drive. Check exhaust bellows

- Inspection of exhaust hose and cooling water hoses

- Check hoses/pipes, unions, and hose clamps

- Check the condition of all rubber hoses, and re-tighten hose clamps

- Outboard drive. Change universal joint bellows

- Thoroughly inspect all hydraulic hoses and fittings for signs of leaks,

wear, cracks, or aging - EVC system. Inspection with the diagnostic tool

It’s not JUST and oil change! Also remember to follow your Generator Manufacturers recommended maintenance as well!

A well-maintained engine is a sign of a well-maintained boat overall. When a potential buyer is looking at a boat, they will pay attention to the condition of the engine, as it is a crucial component of the vessel. If the engine has been properly maintained, it can give the buyer confidence that the rest of the boat has also been well-maintained.

Well-maintained engines will last longer and perform better. Regular maintenance, such as oil changes, filter replacements, and belt adjustments, can help prevent problems and extend the life of the engine. A poorly maintained engine may have reduced performance, reduced fuel efficiency, and even require expensive repairs or replacement, which can decrease the boat’s value.

A properly maintained engine will be more reliable and safe. This can give potential buyers peace of mind knowing that the boat is less likely to break down or experience mechanical issues while out on the water. This can be particularly important for buyers who plan to use the boat for long trips or in rough waters.

Regular maintenance can help prevent small issues from becoming larger, more expensive problems. This can save the owner money in the long run, as it can prevent the need for costly repairs or replacement parts. Potential buyers will appreciate knowing that the boat has been well-maintained and may be willing to pay a higher price for it.

In summary, maintaining your marine diesel engine can increase the value of your boat by signaling to potential buyers that the boat has been well-maintained, increasing the engine’s longevity and performance, increasing reliability and safety, and preventing small issues from becoming larger, more expensive problems later on.